- Introduction: The Cost of Choosing the Wrong Tube Bundle Extractor

For petrochemical plants and refineries, a tube bundle extractor isn’t just another piece of equipment—it’s a critical tool that directly impacts turnaround (T/A) costs, safety records, and long-term operational efficiency. Choosing an undersized, unreliable, or ill-suited extractor can lead to:

Extended downtime (costing $10,000–$100,000 per hour in lost production).

Safety incidents (from bundle slippage or equipment failure).

Unplanned maintenance costs (for repairs or replacements).

Reduced exchanger lifespan (from improper handling).

Diesel-driven tube bundle extractors are increasingly popular for their mobility and independence from site power—but not all diesel models are created equal. At Dalian Qingwei Industrial Equipment Co., Ltd., we’ve helped hundreds of petrochemical clients select the right extractor for their needs. This guide breaks down everything you need to know: from pricing factors to key features, and from selection mistakes to after-sales support—to ensure you make an investment that pays off for years. - Understanding Diesel Tube Bundle Extractor Pricing: What Drives Costs?

One of the first questions we hear from clients is, “How much does a diesel tube bundle extractor cost?” The answer depends on several key factors—there’s no “one-size-fits-all” price. Below is a detailed breakdown of the elements that influence pricing, so you can understand where your budget is going and avoid overpaying for unnecessary features.

2.1 Pulling Capacity (Tonnage): The Foundation of Pricing

Pulling capacity (measured in tons) is the most significant pricing factor. Our models range from 10T to 115T, and each tonnage class corresponds to a different price tier:

10–30T Models: Ideal for small heat exchangers (bundles up to 6m long, 50T weight). These are the most affordable options, suitable for regional refineries or maintenance contractors with light-duty needs.

30–70T Models: The “workhorse” category for most petrochemical plants. Handles bundles 6–10m long (up to 80T weight) and is compatible with a wide range of exchanger types.

70–115T Models: For heavy-duty applications (e.g., large pressure vessels, bundles 10–15m long, 115T weight). These require more powerful diesel HPUs and reinforced frames, making them the highest-priced standard models.

Tip: Always choose a model with a pulling capacity 20% higher than your heaviest bundle (the “safety factor”). Undersizing to save money will lead to overload failures and costly downtime.

2.2 Bundle Length & Diameter: Customizations Add Cost

The size of your bundles directly impacts the extractor’s design—and price. Here’s how:

Length: Standard models handle bundles up to 12m, but if you need to work with 12–15m bundles, we’ll add extended travel rails (increasing cost by 15–25%).

Diameter: Bundles with diameters over 2m require wider clamps and reinforced travel systems (adding 10–20% to the base price).

Structural Enhancements: For bundles with irregular shapes or heavy end caps, we’ll add custom clamping jaws or support brackets—these can increase costs by 5–30%, depending on complexity.

2.3 Controls & Safety Options: Investing in Peace of Mind

Safety and control features are non-negotiable—and they affect pricing. Here are the most common options and their cost impacts:

Wireless Remote Control: A must for large job sites. Adds 8–15% to the base price, but eliminates the risk of tripping over wires and lets operators stand at a safe distance.

Soft Start/Stop & Overload Protection: Standard on all our models (no extra cost)—but some competitors charge for these critical safety features.

Dual Limit Switches: Provide an extra layer of protection by stopping movement if the bundle reaches preset limits. Adds 5–10% to the price.

Safety Cameras & Alarms: For hazardous areas (Ex zones) or low-visibility sites. Cameras let operators see the clamp/bundle alignment, while alarms warn of overload or low oil pressure. Adds 12–20% to the cost.

2.4 Customization: Tailoring the Extractor to Your Site

Every petrochemical plant has unique challenges, and customizations ensure the extractor works for you—not the other way around. Common customizations and their costs include:

Corrosion-Resistant Coatings: For coastal plants or sites with high humidity. Adds 8–15% (uses epoxy or zinc-rich coatings to prevent rust).

Low-Temp Kits: For cold climates (temperatures below -10°C). Include heated HPUs and low-viscosity hydraulic oil. Adds 10–20%.

Rail Systems: For uneven terrain (e.g., gravel yards or outdoor job sites). Rails keep the extractor stable during travel. Adds 15–30% (depending on rail length).

Spare Parts Kits: Include essential components (hoses, filters, seals) for quick repairs. Adds 5–10% but saves time during emergencies.

2.5 Delivery Scope: What’s Included in the Price?

Be sure to ask suppliers what’s included in the quoted price—some cut corners by excluding critical services. Our standard delivery scope includes:

Factory Acceptance Test (FAT): Free of charge—we invite you to test the machine at our Dalian factory.

Shipping: Door-to-door delivery (by sea or land) to your site—included in the price for most regions.

On-Site Training: 1–2 days of training for your operators and maintenance team—no extra cost.

Warranty: 12-month standard warranty (extendable to 24 months for 5–10% extra).

After-Sales Support: 24/7 technical support (via phone, WhatsApp, or email)—free for the first year.

Competitors may charge separately for these services, so always compare “total cost” rather than just the base price. - Key Features to Look for in a Diesel Tube Bundle Extractor

Not all diesel extractors offer the same level of performance or safety. Below are the non-negotiable features you should demand from any model you consider—and how our Dalian Qingwei extractors stack up.

3.1 High-Quality Diesel HPU: The “Heart” of the Machine

The diesel HPU is responsible for powering all functions, so it must be reliable. Our HPUs include:

Tier 4 Final Engines: Meet global emissions standards (e.g., EPA Tier 4, EU Stage V) to reduce environmental impact.

Fuel Efficiency: Designed to use 10–15% less diesel than competitors’ HPUs—saving money on fuel over time.

Easy Maintenance: Accessible oil filters and fuel tanks, so routine checks take minutes.

3.2 Robust Clamping Mechanism: Prevent Bundle Slippage

A weak or poorly designed clamp is the #1 cause of safety incidents. Our clamping systems feature:

Automatic Centering: Ensures the bundle is aligned perfectly, reducing wear on the exchanger.

Uniform Pressure Distribution: Uses multiple hydraulic cylinders to apply even pressure—no more bundle slippage.

Wear-Resistant Jaws: Made from hardened steel (RC 50–55) to withstand repeated use. Jaws are replaceable (low cost) when worn.

3.3 Smooth Travel System: Reduce Cycle Time

The travel system determines how quickly you can move the extractor and bundle. Our system includes:

Dual Drive Motors: Provide consistent speed (0.5–2 m/min) even when carrying heavy bundles.

Brake System: Automatic brakes engage when the machine stops—prevents rolling on slopes.

Adjustable Track Width: For narrow or wide job sites (track width can be adjusted from 1.5m to 3m).

3.4 Intuitive Controls: Minimize Operator Error

Complex controls increase the risk of mistakes. Our extractors feature:

User-Friendly Remotes: Wired or wireless remotes with large, labeled buttons and a digital display (shows pulling force, speed, and oil temperature).

One-Button Cycles: Pre-programmed “extract” or “push” cycles—reduces the number of steps operators need to take.

Emergency Stop (E-stop): Large, red button on both the remote and the machine itself—easy to access in emergencies.

3.5 Comprehensive Safety Features: Protect Your Team

Safety should never be an afterthought. Our extractors include:

Overload Protection: Automatically stops the machine if pulling force exceeds the rated capacity.

Limit Switches: Prevent the bundle from being pulled too far or pushed too hard.

Oil Temperature Monitoring: Alerts operators if the hydraulic oil gets too hot (prevents HPU damage).

Noise Reduction: HPUs are enclosed in sound-dampening boxes (noise level <85 dB)—protects operators’ hearing. - Common Mistakes to Avoid When Buying a Diesel Tube Bundle Extractor

Even experienced petrochemical plant managers make mistakes when selecting an extractor. Below are the most frequent pitfalls—and how to steer clear of them.

4.1 Mistake #1: Choosing the Wrong Tonnage

Many clients choose an undersized extractor to save money, but this leads to overload failures. For example, a 50T extractor trying to pull a 60T bundle will overheat the HPU, damage the hydraulic system, and potentially cause the bundle to slip. Always add a 20% safety factor to your heaviest bundle weight.

Solution: Calculate your maximum bundle weight (including end caps and attachments) and choose an extractor with a pulling capacity 20% higher. Our team can help you confirm the right tonnage.

4.2 Mistake #2: Ignoring Site Conditions

Outdoor job sites, cold climates, or uneven terrain require specialized features. For example, a standard extractor used in a -20°C environment will have frozen hydraulic oil, rendering it useless.

Solution: Share your site’s details (temperature range, terrain, indoor/outdoor use) with the supplier. We’ll recommend customizations (e.g., low-temp kits, rails) to ensure the extractor works in your conditions.

4.3 Mistake #3: Overlooking After-Sales Support

A great extractor is only as good as the support behind it. If your machine breaks down during a turnaround, you need fast help—not a 48-hour wait for a technician.

Solution: Ask suppliers about their after-sales support:

Do they offer 24/7 technical support?

How quickly can they send spare parts?

Do they provide on-site repairs?

At Dalian Qingwei, we offer 24/7 support and can ship spare parts to most regions within 3–5 days.

4.4 Mistake #4: Focusing Only on Price

The cheapest extractor may seem like a good deal, but it will cost more in the long run. Low-quality models use inferior components (e.g., cheap hydraulic hoses, weak frames) that break frequently, leading to downtime and repair costs.

Solution: Compare total cost of ownership (TCO) instead of base price. A slightly more expensive, high-quality extractor will have lower maintenance costs, longer lifespan, and fewer downtime incidents—saving you money over 5–10 years. - Our Dalian Qingwei Diesel Tube Bundle Extractor Models: A Quick Overview

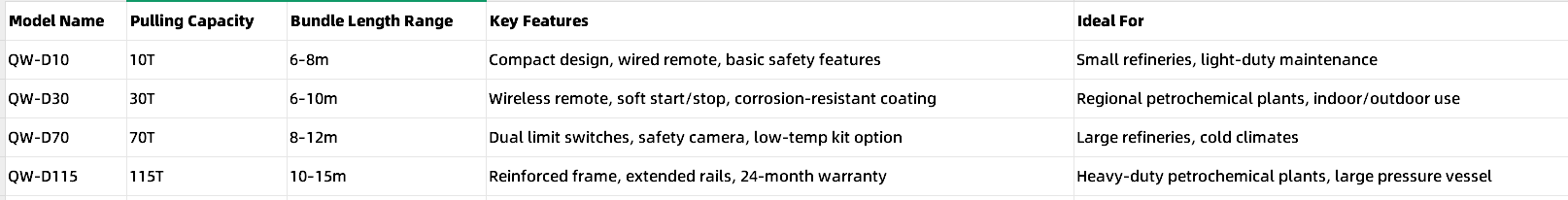

To help you narrow down your options, here’s a snapshot of our most popular models for petrochemical plants:

- How to Request a Custom Quote from Dalian Qingwei

Getting a custom quote from us is fast and easy—follow these steps:

Step 1: Gather Your Requirements

Before contacting us, collect the following information (use our checklist from Section 4 of Article 1):

Maximum bundle weight (with 20% safety factor).

Maximum bundle length and diameter.

Site conditions (indoor/outdoor, terrain, temperature range).

Desired control mode (wired/wireless) and safety features.

Any customizations you need (e.g., low-temp kits, rails).

Step 2: Contact Our Team

Reach out to us via:

WhatsApp/Phone: +86 186 2443 3099 (available 24/7 for urgent inquiries).

Email: info@qingweiequipment.com (send your requirements, and we’ll reply within 12 hours).

Website: Visit our contact page to submit a form (include your company name, location, and requirements).

Step 3: Review Our Proposal

We’ll send you a detailed proposal within 24 hours, including:

Recommended model (with specifications).

Pricing breakdown (base price + customizations).

Lead time (typically 4–6 weeks).

Delivery scope (what’s included in the price).

Warranty and after-sales support details.

Step 4: Factory Acceptance Test (FAT)

Once you approve the proposal, we’ll start manufacturing. Before delivery, we’ll invite you to our Dalian factory to test the machine—you can check performance, safety features, and customizations to ensure they meet your standards.

Step 5: Delivery & Training

We’ll ship the extractor to your site (door-to-door) and send a technician for on-site training. Our team will stay in touch after delivery to answer questions and provide support. - Conclusion: Invest in a Diesel Tube Bundle Extractor That Grows with Your Plant

Choosing the right diesel tube bundle extractor is a decision that will impact your petrochemical plant’s efficiency and safety for years. By focusing on pulling capacity, safety features, customizations, and after-sales support—not just price—you can select a model that handles your current needs and adapts to future growth.

At Dalian Qingwei Industrial Equipment Co., Ltd., we don’t just sell extractors—we partner with you to understand your challenges and deliver a solution that works. Our diesel tube bundle extractors are built to last, designed for safety, and tailored to your site’s unique needs.

Ready to get started? Contact our team today for a custom quote—and take the first step toward faster, safer, and more efficient turnarounds.