- Introduction: Why Refineries Can’t Afford to Compromise on Tube Bundle Extraction

In the high-stakes world of refineries and petrochemical plants, turnaround (T/A) operations are make-or-break moments. Every minute of unplanned downtime eats into profits, and safety lapses can lead to catastrophic consequences. Among the critical equipment that defines the success of these turnarounds is the tube bundle extractor—a machine designed to pull out or push in exchanger bundles safely, efficiently, and with minimal disruption.

While electric tube bundle extractors have their place, diesel-driven models have emerged as the go-to choice for many refineries and maintenance contractors—and for good reason. At Dalian Qingwei Industrial Equipment Co., Ltd., we’ve engineered our diesel tube bundle extractors to address the unique challenges of outdoor yards, remote job sites, and areas with limited utility access. This article dives deep into what makes our diesel extractors stand out, how they optimize turnaround workflows, and why they’re a long-term investment in your operation’s productivity and safety. - What Sets Our Diesel Tube Bundle Extractor Apart? Core Design & Working Principle

Our diesel tube bundle extractor is powered by a high-performance diesel Hydraulic Power Unit (HPU)—the heart of the machine that delivers consistent power to every critical function: clamping, pulling/pushing, traveling, and braking. Unlike electric models that rely on fixed power sources, our diesel HPU offers unmatched mobility, letting you move the extractor freely across job sites without worrying about extension cords or generator access.

2.1 Step-by-Step Workflow (Proven in Live Factory Operations)

Every component of our extractor is designed to streamline the extraction process, reducing human error and cutting down on turnaround time. Here’s how it works in real-world scenarios:

Lifting & Positioning: The extractor is maneuvered to the exchanger using its built-in travel system, with precise controls to align it perfectly with the bundle—no need for extra crane adjustments.

Centering & Clamping: Our patented clamping mechanism automatically centers the bundle and applies uniform pressure to secure it. This eliminates the risk of slipping (a common issue with generic extractors) and protects the bundle from damage.

Extract/Push: The diesel HPU delivers steady, adjustable pulling force (ranging from 10T to 115T) to pull the bundle out or push it back in. Unlike jerky electric models, our soft-start/stop feature prevents sudden jolts that could harm the exchanger or the bundle.

Travel/Transfer: Once extracted, the extractor travels smoothly to move the bundle to a maintenance area—no need to switch between multiple pieces of equipment.

Unclamp & Reset: The clamp releases gently, and the machine resets to its initial position, ready for the next cycle.

Safety Checks: Built-in sensors trigger automatic safety checks (e.g., oil temperature, clamp pressure) after each cycle, ensuring the machine is always in optimal condition. - Key Advantages: Tested in Real Refinery Turnarounds

We don’t just design equipment—we test it in the harshest refinery environments to ensure it delivers on its promises. Here are the advantages our customers consistently highlight:

3.1 Unmatched Reliability (Even in Extreme Conditions)

Refinery turnarounds can’t wait for equipment breakdowns. Our diesel extractors feature:

Optimized Hydraulics: High-quality hydraulic hoses and valves that resist wear, corrosion, and high temperatures (up to 60°C in standard models, with low-temp kits available for -20°C environments).

Comprehensive Protection: Overload protection (prevents damage from excessive force), limit switches (stops movement at preset limits), and an emergency stop (E-stop) button that cuts power instantly in case of danger.

Durable Construction: A heavy-duty steel frame that withstands impacts and vibrations—critical for busy job sites where equipment is often moved between tight spaces.

3.2 Efficiency That Cuts Turnaround Time by Up to 30%

Time is money in refineries, and our extractors are built to save both:

Adequate Pulling Force: With models ranging from 10T to 115T, we can handle bundles of all sizes—from small 6m units to large 15m bundles (with customizations for even longer lengths).

Steady Travel Speed: Adjustable travel speeds (0.5–2 m/min) let operators balance speed and precision, reducing the time spent moving bundles between locations.

Reduced Crane Dependency: Unlike manual extraction methods that rely on cranes for every step, our extractor handles positioning, pulling, and transfer—freeing up cranes for other critical tasks.

3.3 Versatility for Every Job Site

No two refineries are the same, which is why our diesel extractors are designed to adapt:

Wide Load Range: 10–115-ton classes cover everything from small heat exchangers to large pressure vessels.

Compatible with All Bundle Sizes: Works with bundles 6–12m long (up to 15m with custom rails) and diameters up to 3m.

Customizable Features: Add rails for uneven terrain, corrosion-resistant coatings for coastal refineries, or low-temp kits for cold-climate operations—we tailor the machine to your site’s needs.

3.4 Ease of Use & Low Maintenance

We know your team has enough to handle during turnarounds—so we made our extractors simple to operate and service:

Dual Control Modes: Wired or wireless remote control (with a 50m range) lets operators stand at a safe distance while maintaining full control. The remote features intuitive buttons and a digital display for real-time data (e.g., pulling force, travel speed).

Accessible Components: All critical parts (HPU, hydraulic filters, clamp mechanisms) are easy to reach, so maintenance checks and repairs take minutes—not hours.

Long Service Intervals: Our extractors require maintenance only every 500 operating hours (compared to 300 hours for competitors), reducing downtime and maintenance costs.

3.5 Cost Performance: Lower Total Cost of Ownership (TCO)

Investing in a diesel tube bundle extractor isn’t just a purchase—it’s a long-term investment. Our models deliver lower TCO by:

Reducing Downtime: Faster extraction cycles mean turnarounds finish on time (or early), minimizing lost production.

Lower Maintenance Costs: Durable components and long service intervals cut down on repair bills.

No Hidden Costs: We include essential accessories (e.g., spare hoses, filter kits) in the base package, so you won’t face unexpected expenses. - How to Choose the Right Diesel Tube Bundle Extractor: Our Expert Checklist

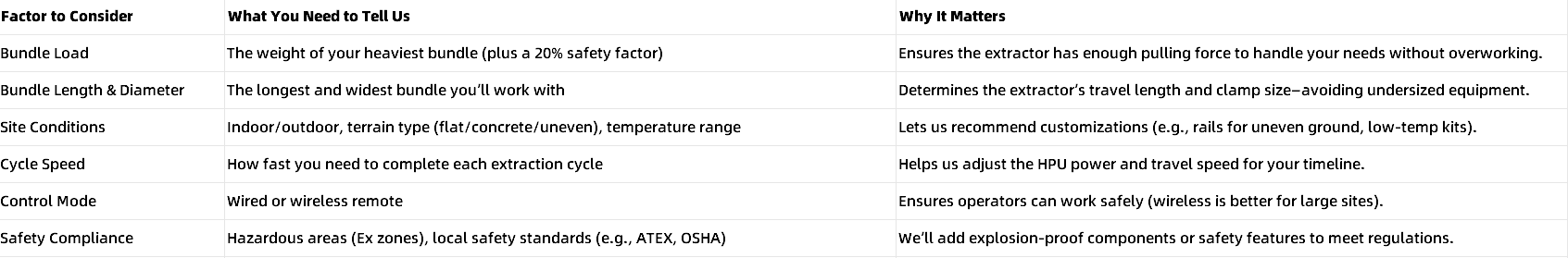

Choosing the wrong extractor can lead to delays, safety risks, and wasted money. To help you select the perfect model for your needs, we’ve created a simple checklist—share these details with our team, and we’ll provide a customized quote in 24 hours:

- Operation & Safety: Our Commitment to Keeping Your Team Safe

Safety is non-negotiable at Dalian Qingwei—and our diesel tube bundle extractors are designed with that in mind. Here are the key safety guidelines we recommend (we also include formal training for your team during delivery):

Pre-Operation Checks: Inspect clamp wear (replace if wear exceeds 3mm), oil temperature (should be 30–50°C), and hose fittings (tighten any loose connections) before each use.

Safe Operation: Never stand in the “line of force” (the area directly in front of or behind the bundle during extraction). Keep bystanders at least 10m away from the working area.

Troubleshooting: If the machine detects overload, skew, or jamming, it will automatically stop. Do not force the machine—contact our support team for guidance.

Operator Training: Only trained personnel should operate the extractor. We provide on-site training for operators, signalers, and riggers to ensure everyone understands the machine’s limits and safety protocols. - Real-World Use Cases: How Our Customers Benefit

Our diesel tube bundle extractors are trusted by refineries and maintenance contractors worldwide. Here are two examples of how they’ve made a difference:

Case 1: Large Refinery Turnaround in North China

A refinery in Shandong needed to replace 12 exchanger bundles (each 10m long, 80T) during a 10-day turnaround. Using our 100T diesel extractor, their team completed the job in 8 days—2 days ahead of schedule—by reducing crane dependency and cutting extraction time per bundle from 4 hours to 2.5 hours.

Case 2: Mobile Maintenance Contractor in Southeast Asia

A contractor that services multiple refineries needed a portable extractor. Our 50T diesel model (with wireless remote and expandable clamps) let them handle bundles of varying sizes across 5 sites—eliminating the need to transport multiple machines. - Procurement & Delivery: A Smooth Process from Quote to After-Sales

We want to make it easy for you to get the right equipment. Here’s our procurement flow:

Share Your Requirements: Send us your checklist (bundle load, length, site conditions, etc.) via WhatsApp (+86 186 2443 3099) or email (info@qingweiequipment.com).

Model Proposal: Our team will recommend a customized model, including lead time (typically 4–6 weeks) and spare parts kits.

Quotation & PO: We’ll send a detailed quotation (with pricing breakdown and warranty terms). Once you confirm the PO, we start manufacturing.

Factory Acceptance Test (FAT): Before delivery, we invite you to inspect and test the machine at our Dalian factory—ensuring it meets your standards.

Delivery & Training: We ship the extractor to your site (with door-to-door service) and provide on-site training for your team.

After-Sales Support: We offer a 12-month warranty (extendable to 24 months) and 24/7 technical support—so you’re never alone if you need help. - Contact Us Today to Optimize Your Turnaround

Ready to reduce downtime, improve safety, and cut costs with a diesel tube bundle extractor that’s built for your needs? Reach out to our team now:

WhatsApp/Phone: +86 186 2443 3099

Email: info@qingweiequipment.com

Address: Dalian Qingwei Industrial Equipment Co., Ltd., Dalian, Liaoning, China

At Dalian Qingwei, we don’t just sell equipment—we partner with you to make your refinery turnarounds safer, faster, and more efficient. Let’s build a solution that works for you.